Back in the day of simplicity, a Clutch Replacement is much less of a headache than even the mere Performance Tire upgrade on your modern car today; it is all working around pure mechanical principles.

Here is a schematic diagram of such simple mechanical process depicting the main components of manual transmission Clutch and their functioning purposes. Though enabling torque to be transmitted to the drive shaft requires several physical chain reactions, it essentially starts off with applying pressure on clutch lining to touch the rotating flywheel.

designated friction process momentarily appears between the two components; it begins with sufficient friction forces to allow quick engagement and then most importantly to the normal holding forces existence during the engagement period, which where the designed amount of torque being produced can be transmitted through without any slippage.

designated friction process momentarily appears between the two components; it begins with sufficient friction forces to allow quick engagement and then most importantly to the normal holding forces existence during the engagement period, which where the designed amount of torque being produced can be transmitted through without any slippage.Material selection and design calculation is mainly focusing into two critical functions, namely the onset and during engagement, taking into account the worst scenario of torque load being transmitted.

This actually necessitates the engineers to calculate other impacts such as stresses, strains and thus torque transmission losses being generated, but it may extend also into the area of designated parts lifetime as well as economic senses from the manufacturing perspective itself.

When you are driving on ascending section of the hilly part of your town on the way to the favorite lookout point, the engine works the hardest to overcome the load, the optimal torque rather than horsepower is the key to ensure you can arrive at the spot where the city view is at its best. There are certainly many considerations to design a suitable Clutch to suit the required application with specific holding-capacity.

The survival of the fittest does matter for the material selection, the ability to provide certain calculated friction forces from the clutch lining material, its useful working friction ranges to ideally suited engine and load characteristic. Cargo load requires huge amount of torque at low engine speed, a characteristic normally belong to big displacement engine or diesel powered vehicle. A speed demon load on the contrary requires different kind of engineering parameter.

This ongoing engage and disengaging processes follow the above mentioned Mechanical Principle throughout the whole of your driving period, all the way to the top of the lookout point and beyond, working out the shifter has become the reflective chores to your limbs. That is until the invention of Automatic Transmission.

As the technology advances so does the demand for ease of shifting the gear, the Automatic Transmission could now shift itself based on the load creating nice comfortable driving chores.

No longer is a driver’s focus being distracted by the shifting process, more concentrations toward the condition of the road ahead; a real bonus as perhaps representing by the long by gone jargon of “Passive Safety System”.

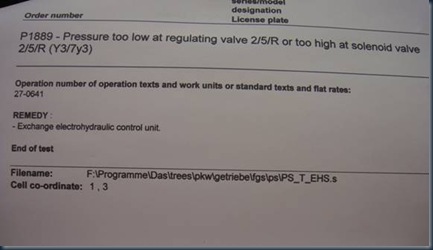

In addition to have multiple Clutches, today modern Automatic Transmission also consists of complex computerized electro hydraulic mechanical devices lumped together that works upon various sensory readings. A number of systems have in fact can have the flexibility to adapt to your personal driving style. Simplicity is simply the bygone era; Clutch Replacement is now posing a huge big headache.

2 comments:

Very nice, now I have learned something I can ponder regarding this matter and the use of the same. I would like to learn more about it and make a little blog about the same. Quickstart az would like to thank you for this. Thanks for sharing!

Thanks for providing this information. Very helpful

Post a Comment